Has sheltering in place left you feeling cooped up and wishing for a little adventure? We get it. We’re all longing for those carefree moments out in the world, discovering new or reconnecting with old pursuits. While we might be feeling constrained physically and intellectually, many of us are taking on new challenges. The eqpd team has been in heavy R&D mode the past couple of months, exercising our creativity and ingenuity as we respond to the COVID-19 challenge. We’ve gone from making LastBags to making basic masks to, now, manufacturing our own design - The DailyMask. We thought you might be interested in learning about our product design process. See its development here.

First, some background. When we started making the requested "3 pleat surgical masks" back in March, like all designers, we were very critical of this basic design. We questioned everything about them:

How they fit, how they worked, how hard or easy they are to wear, how they made you look, or feel, how breathing felt, why put elastic around the ears or head? Why was the 3 pleat design chosen by so many hospitals? Do they have to be N95? What materials are the best? Can we even get those materials in this global pandemic? Can we improve or add value? Should we even try to make something unique? Or just copy an existing design? If we create a new product , will it help fulfill the eqpd mission? Using the principles of Industrial Design to create everyday products that respect all people and the environment.

To this final question, we answered yes . . . What an opportunity to use our education and experience to help keep our community safe and design a respectful, quality product. Eight weeks later we are launching the DailyMask - eqpd's answer to a reusable cloth face mask.

Step 1 - Copy and Create

Step 1 - Copy and Create

This is where most designs start . . . looking at the existing offerings and trying to understand the attributes that make them valuable. So we made basic 2 and 3 pleat cloth surgical masks like the home sewers were being asked to make, and then elaborated on how those pleats might behave in our first round of prototypes.

Step 2 - Create more

Step 2 - Create more

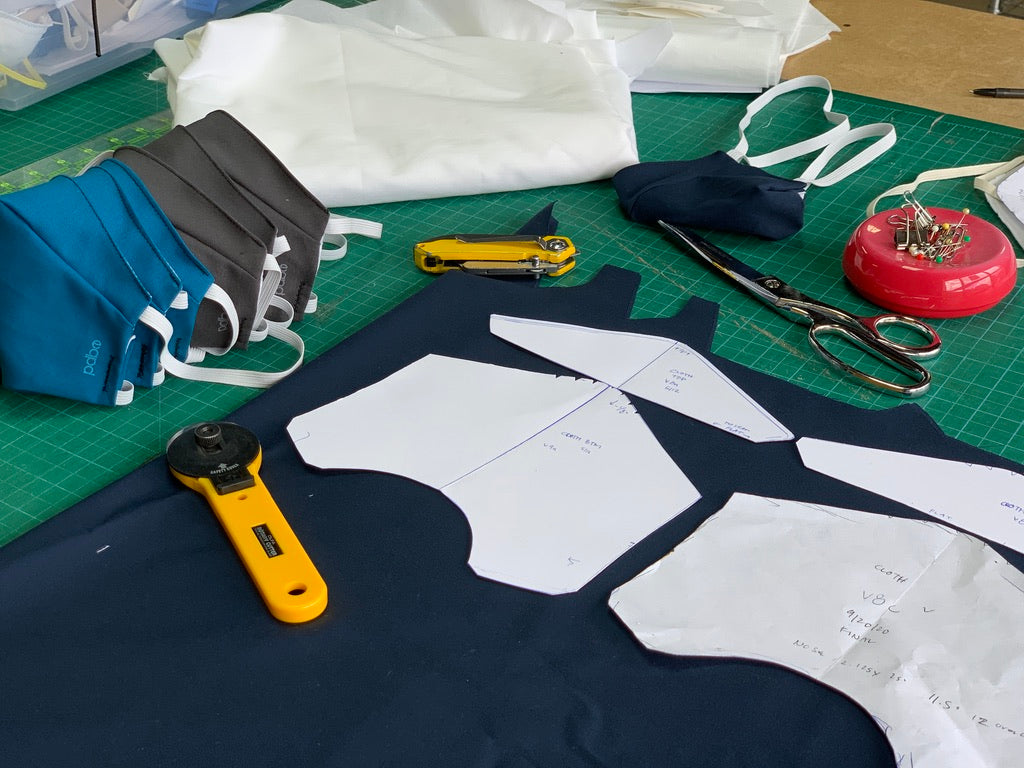

Now the task becomes “can we do it better?” So we set our expectations high and start building . . . and though we draw very well, we don't spend much time sketching on paper, because the only thing that matters is the object. So we sketch in 3D. Letting materials behave naturally - bending, folding and draping, as to create designs that are not “overworked”. Designs that inherently have a clean and approachable appearance because they are simple and the materials are used in their most beneficial way. But they sure don’t start that way. Designs get very messy before they reveal themselves.

Step 3 - Commit

Most projects don’t have such pressing deadlines as a pandemic, so the pressure to create quickly was stressful. Combined with our commitment to not copy others and to create a fresh, approachable aesthetic was a lot to process. But that’s exactly why eqpd is here. We are confident in our ability to create honest solutions because we respect the process and design for humankind. It’s the highest pinnacle of Industrial Design and can affect the most people, so we want to have the most positive impact we can. So we commit, and start to refine our own list of pro’s and con’s, always being thoughtful of our customers and adding value to their lives.

Step 4 - Keep Building

Step 4 - Keep Building

Refinement is relentless. Because we design and manufacture under one roof, we keep a very close relationship between the two. One reason our designs are “simple” is because they have to be. We have deep admiration for the talent it takes to manufacture and when you approach designs with this respect you create products that are actually nice to build. But to get to that result, you need designers that are fussy and find lots of enjoyment in “building the same thing, with one small adjustment” over and over again and you need sewers that are just as picky and committed to delivering exceptional products.

Step 5 - Version 1 is Born

Step 5 - Version 1 is Born

Once we find a balance of design and production, we invest in cutting dies and fabrics to begin the first round of production. This puts our concepts to the test. We build hundreds of identical products for field testing. We enlisted doctors, nurses, EMT’s, law enforcement, Forest Service, fisheries and agricultural workers, cider makers, vintners, building contractors, welders, pilots, grocery and retail employees, grandparents, children and ourselves to try our product and provide feedback. We want our designs to work for a wide range of uses and expectations, so we test with a very diverse cross section of our community.

Step 6 - Available soon

With a clean trim fit, subtle details and friendly aesthetic, the development of our DailyMask was the result of 20 years of design and manufacturing experience under the pressure of an entirely new challenge. We feel good to have created a mask that feeds full-circle into our design ethos and to have further educated ourselves on the value of good design.

Sign up for our email newsletter below to find out when you will be able to order The DailyMask. For bulk sales, connect with us at info@eqpdgear.com.